MECHANICAL WORKINGS

At the Vigasio headquarters, A.T.E. srl complements its production of technical blow-molded items with an in-house mechanical workshop, which represents a real strength for the company.

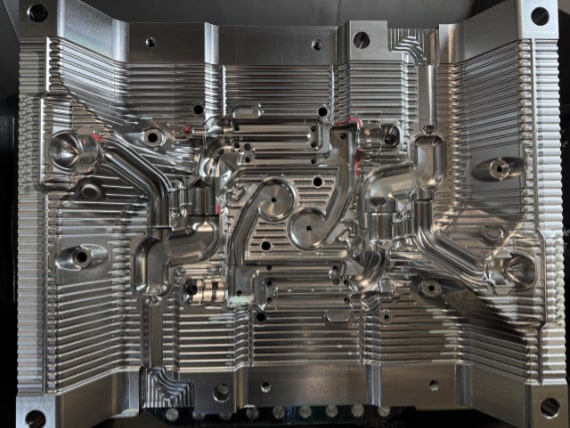

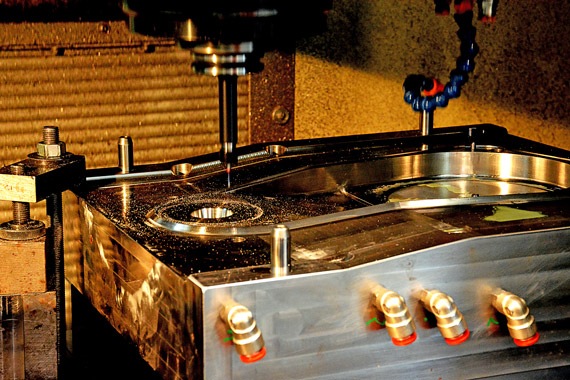

Thanks to a comprehensive range of machinery—including 3 and 5-axis machining centers, CNC lathes, and wire EDM systems—we are able to manufacture molds, equipment, and complex mechanical components in both steel and aluminum entirely in-house.

This production autonomy enables us to respond quickly and accurately to customer needs, ensuring a high level of quality and flexibility.

The close integration between our workshop, design department, and internal automation team also allows us to develop tailor-made solutions optimized at every stage: from design to production, all the way to commissioning.

Thanks to our in-house workshop, we are also able to build everything needed for our automated lines, which are described on this page.

CNC Machining Center

DMG MORI DMU 95 monoBLOCK

The DMG MORI DMU 95 monoBLOCK is a high-performance 5-axis machining center, ideal for the construction of complex and precision molds.

Its monoblock structure ensures rigidity and stability even in the most demanding machining operations.

With a spindle of up to 20,000 rpm and Heidenhain control, combined with the Powermill CAM software, it guarantees excellent finishes and reduced cycle times.

It is designed to handle large pieces up to 1,000 kg with maximum precision.