MASS PRODUCTIONAND FUNCTIONAL SAMPLINGS

Thanks to consolidated thirty years of experience , the high trained and qualified staff and the fully automated production facility, A.T.E. srl is distinguished by the ability to attend the Client in production that starts from the production of samples and pre-series , up to mass production in the order of million pieces per year.

OUR products

WE OFFER THE HIGHEST LEVEL OF AUTOMATION

AND ATTENTION IN THE CONSTRUCTION

OF COMPLEX ASSEMBLIES

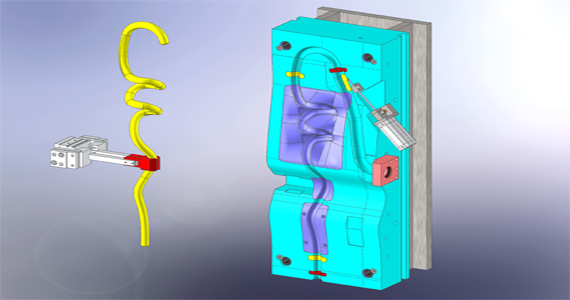

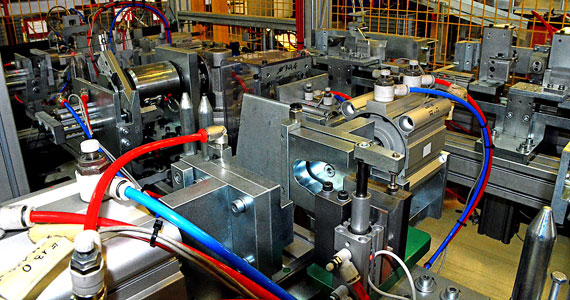

A.T.E srl makes use of its facilities and collaboration with major national manufacturers of automatic lines, to realize their own customized lines suitable for the finishing and 100% testing of the production, as well as boasting of almost faultless mass production.

Our automatic lines are able to perform all the mechanical finishing processes, simultaneously welding, sealing tests, dimensional checks, auxiliary presence checks, ensuring the best economic and strategic advantage to the customer.

The highly qualified staff is able to handle the assembly and implementation of complex systems, using ad-ho designed solutions.